Aarhus University has designed and built a pilot plant for the hydrothermal conversion of biomass into chemicals or fuels that can be mixed with or replace fossil derived petroleum.

The process is popularly known as HTL (hydrothermal liquefaction). Basically, organic materials are mixed with water and subjected to high pressures of 150-350 bar and temperatures of 300-450 degrees. The result after a short process is a viscous oil that can be refined to the full pallet of products also produced in conventional oil refineries. This includes diesel, jet fuel, marine fuel but also aromatic and aliphatic chemicals. The AU pilot plant is currently the largest HTL reactor found in academia worldwide.

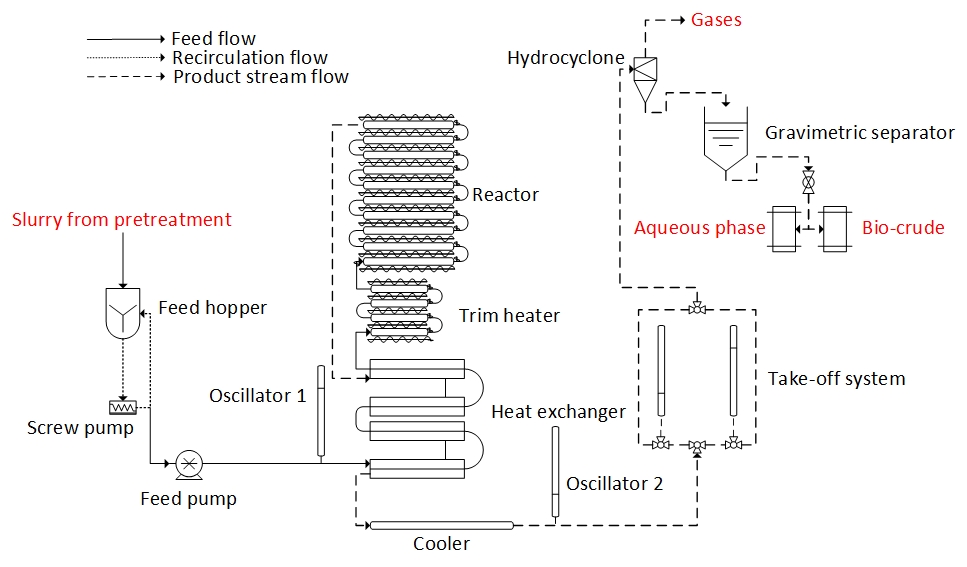

The facility allows the work to be carried out in a continuous process where the pressure is maintained and the heat loss is reduced through heat recovery in an efficient heat exchanger. This means that the plant has a much higher energy efficiency than previous systems.

The design of the pilot plant permits its subsequent upscaling to a demonstration scale and full-scale plant.

The platform will, among other things, support research in:

The HTL technology is particularly attractive for waste feedstocks which are often a burden on producers. We are able to efficiently recover valuable nutrients such as Phosphorous and Nitrogen while producing a valuable bio-crude. Some of the current research topics within HTL include: