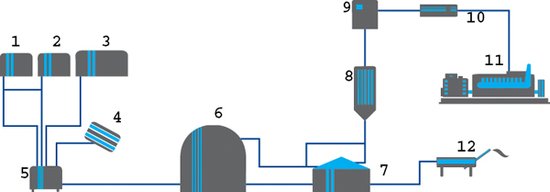

1) Unheated fatty waste tank

Normally contains the additive glycerol, which is used to increase biogas production. Tank volume 75 m3.

2) Heated fatty waste tank

Is mainly used for additives that require eating, such as fish oil. Tank volume 75 m3.

3) Slurry reception tank

For raw slurry from pigs, cattle and fur animals. Tank volume 600 m3.

4) Solids feeder

For solid biomasses such as silage and various by-products. Feeder volume is 50 m3, which corresponds to ca. 28 t (or roughly one day's worth of solids).

5) Dosage module

Fats, raw slurry and solids are mixed and heated to ca. 52 Celcius before being pumped into the reactor. The mixing ratio could be one part fat, 10 parts raw slurry and two parts solids.

6) Reactor

A 1200 m3 tank for biomass digestion. Daily gas production is ca. 4800 m3. The biomass has an average retention time in the reactor of 15 days before pumped to the secondary digester.

7) Secondary digester

The gas is stored in concrete tanks between the slurry and an airtight membrane. The gas production continues in the secondary digester as the biomass is not fully digested. Tank volume 5000 m3.

8) Gas purification

Biological gas scrubbing to reduce the hydrogen sulphide concentration to below 100 ppm (to reduce corrosion of the engine).

9) Gas cooler

Cools the biogas so most of the water vapour condenses out and does not condense in the gas pipes.

10) Gas blower

Increases the pressure to ca. 200 mbar, so that entry pressure at the gas engine, which is about 1.5 km from the biogas plant, will be ca. 150 mbar.

11) Engine

12-cylinder Jenbacher 312, generator effect max 625 kW. Normal daily output 10,000 kWh electricity and 14,000 kWh heat.

12) Decanter centrifuge

Enables the separation of slurry into two fractions: a solid fraction with a high dry matter content (25% - 30%), and a liquid fraction.

During autumn 2011 the plant will be extended with equipment for intake and pretreatment of meadow grass.